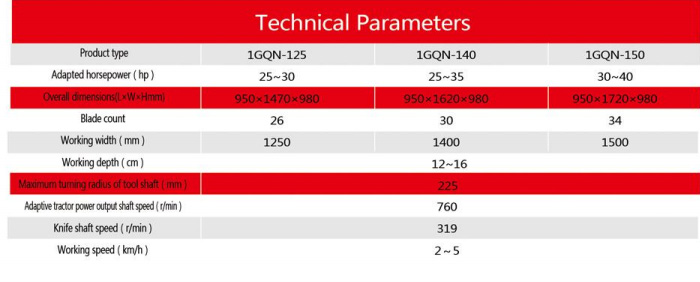

1GQN greenhouse king series rotary tiller

Series model:125/140/150/160

Shenghe series rotary tiller adopts reinforced frame, intermediate transmission, horizontal shaft design, and tractor supporting to complete the ploughing and harrowing operations.

![]()

This machine adopts a self-developed frame structure, which not only improves the stiffness and strength of the entiremachine, but also facilitates the installation of other working components (such as sowing device, fertilization device, deep loosening device, etc.), achieving multi-purpose and improving work efficiency, which is conducive to achieving agricultural season and fullyutilizing the power of the tractor. The upper cover adopts an openable structure, making it convenient for users to inspect and maintain the blade shaft components;The rotary tiller adopts a double helix arrangement, which has good soil crushing effect andlow power consumption. The independently developed improved blade library (with a patent certificate) is sturdy and durable; The cutter shaft and gearbox output shaft are connected using a keyboard, with good coaxiality and convenient disassembly and assembly; The middle small plow body is a new widened type, effectively improving the quality of operation in the middle area. The side panels and connectors are cut and formed by a laser cutting machine in one go, and over 90% of the welding parts of the machine are welded by intelligent robots, further improving the accuracy of the components. In addition, the various components of the entire machine adopt the electrostatic plasma powder spraying process, and the entire machine is assembled using an assembly line. The gearbox has been tested one by one for running-in, and the flexibility of the cutter shaft rotation is inspected before the entire machine is taken offline.The blades are assembled before leaving the factory, achieving complete assembly, film packaging,and shelf storage and transportation of the entire machine. The rear support plate can be replaced with a rear roller according to operational requirements;The suspension frame is connected to the rear beam by two diagonal pull rods, making the force on the entire machine more uniform during operation. One operation can make the soil fine, the ground flat, and the soil and fertilizer mixed evenly. At the same time, it can cut the root stubble buried below the ground surface, making it easy for sowing and transplanting operations, and has been widely used.